Industrial floor scales play a crucial role in various

industries, including manufacturing, logistics, agriculture, and food processing. These scales ensure accurate weight measurements for shipping, inventory management, and compliance with industry regulations. When choosing an industrial floor scale, one of the key decisions is whether to invest in a portable or fixed model. Each type has its own advantages and drawbacks, making it essential to understand their differences to determine which best suits your business needs.

Understanding Portable Industrial Floor Scales

Portable industrial floor scales are designed for

flexibility and mobility, allowing operators to move them to different locations as needed. These scales typically feature wheels, handles, or lightweight frames that make transportation easy. They are commonly used in warehouses, shipping facilities, and agricultural settings where weight measurements need to be taken in multiple locations.

Advantages of Portable Industrial Floor Scales

Flexibility and Mobility

Can be easily moved to different locations within a facility.

Ideal for businesses that require weight measurements in multiple areas.

Space-Saving Design

When not in use, these scales can be stored away, freeing up floor space.

Suitable for facilities with limited space where a permanent installation isní»t feasible.

Ease of Use and Installation

No need for permanent floor modifications or complex installation procedures.

Can be set up quickly and used immediately.

Cost-Effective

Generally more affordable than fixed scales due to lower installation costs.

Reduces the need for multiple fixed scales by allowing one unit to serve various locations.

Versatility

Can be used indoors and outdoors, depending on the design and durability.

Suitable for industries that require frequent weight measurements in different environments.

Disadvantages of Portable Industrial Floor Scales

Potential Accuracy Variability

Movement and frequent relocation may affect calibration and accuracy.

Requires regular recalibration to maintain precision.

Durability Concerns

May be more susceptible to wear and tear due to constant movement.

Not as robust as permanently installed models.

Limited Weight Capacity

Understanding Fixed Industrial Floor Scales

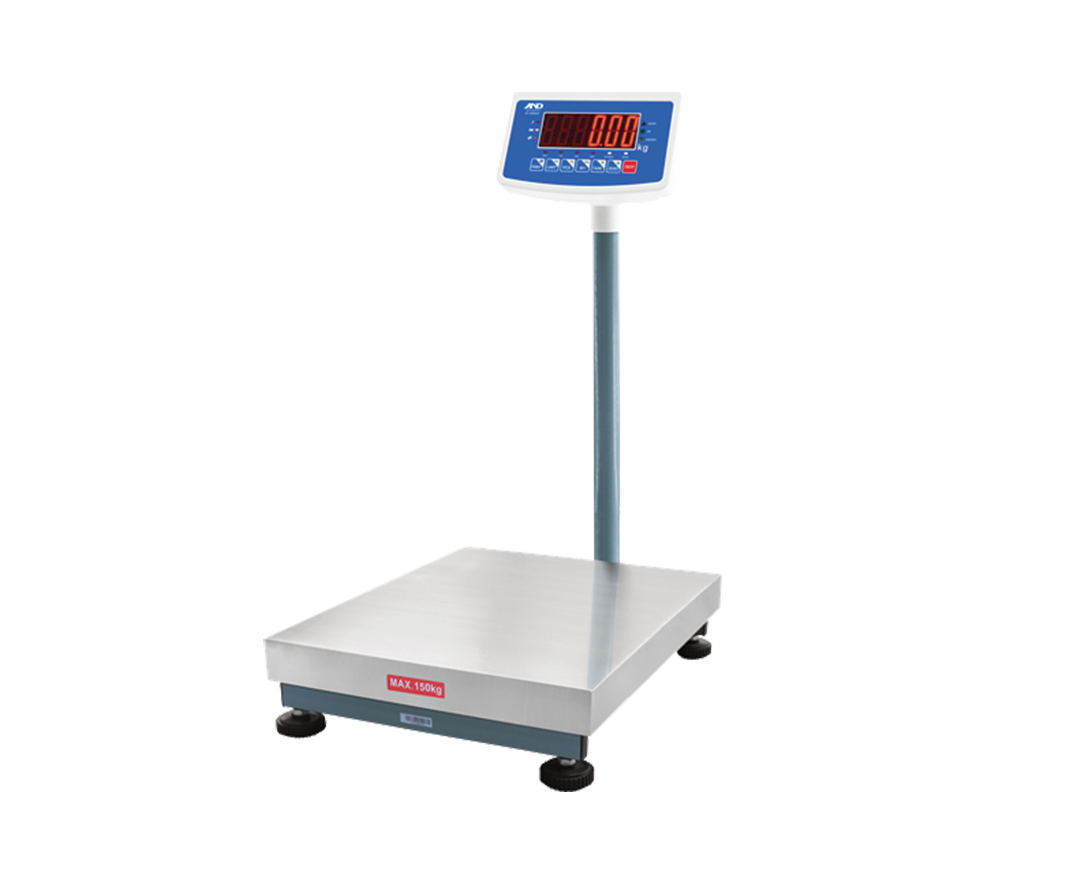

Fixed industrial floor scales are permanently installed in a designated location and are designed for high-precision and heavy-duty weighing. These scales are commonly found in production plants, distribution centers, and bulk material handling facilities where large and heavy loads need to be measured consistently.

Advantages of Fixed Industrial Floor Scales

Superior Accuracy and Stability

Permanently installed, reducing the risk of calibration drift.

Provides highly accurate and consistent measurements.

High Weight Capacity

Can handle much heavier loads compared to portable models.

Ideal for industries that require weighing large containers, pallets, or heavy machinery.

Enhanced Durability

Built with rugged materials to withstand high-traffic industrial environments.

Less prone to damage from movement or relocation.

Automation and Integration

Can be integrated with other industrial systems, such as conveyor belts or automated production lines.

Supports digital tracking and data management for efficient inventory control.

Compliance with Industry Standards

Meets regulatory requirements for industries that require precise weight measurements.

Ideal for applications requiring trade-approved scales.

Disadvantages of Fixed Industrial Floor Scales

Lack of Flexibility

Cannot be moved easily once installed.

Businesses with dynamic workspaces may find it limiting.

Higher Initial Cost and Installation Requirements

Requires professional installation, which adds to the cost.

May need floor modifications, such as reinforced platforms or embedded sensors.

Space Consumption

Occupies a fixed area that cannot be repurposed.

Not ideal for businesses with limited floor space.

Key Considerations When Choosing Between Portable and Fixed Scales

When deciding between a portable and fixed industrial floor scale, consider the following factors:

Frequency of Movement

If your operations require frequent movement of weighing equipment, a portable scale is the better choice.

If weight measurements are always conducted in a single location, a fixed scale provides greater stability and reliability.

Weight Capacity Needs

Portable scales are suitable for medium-duty applications.

Fixed scales are better for weighing heavy loads, such as shipping containers and bulk materials.

Space Availability

If your facility has limited space, a portable scale that can be stored away when not in use may be ideal.

If you have a dedicated weighing area, a fixed scale ensures long-term efficiency.

Budget Constraints

Portable scales have a lower upfront cost and require minimal installation expenses.

Fixed scales, while more expensive initially, offer better durability and long-term accuracy.

Industry Requirements

Certain industries, such as logistics and food processing, may have specific regulatory requirements for weight measurement.

Ensure that the chosen scale meets industry standards for accuracy and compliance.

Use Cases: When to Choose Portable vs. Fixed Scales

When to Choose Portable Industrial Floor Scales

Warehouses that require weighing pallets at different loading docks.

Agricultural businesses that need to weigh produce in different locations.

Construction sites where materials must be measured on the go.

Small businesses that require cost-effective weighing solutions with minimal installation.

When to Choose Fixed Industrial Floor Scales

Manufacturing plants that handle heavy-duty materials.

Logistics and distribution centers that require high-precision weighing.

Food processing plants where compliance with industry standards is crucial.

Businesses that need an integrated weighing system for automated operations.

Conclusion: Which is Right for You?

Choosing between a portable and fixed industrial floor scale depends on your specific operational needs, budget, and industry requirements. If you need flexibility, cost-effectiveness, and mobility, a portable scale is the ideal choice. However, if your business demands high-capacity weighing, superior accuracy, and seamless integration with industrial processes, a fixed scale is the better investment.

By evaluating your workspace, weighing requirements, and long-term business goals, you can make an informed decision that ensures efficiency, compliance, and cost savings. Whether you opt for a portable or fixed model, investing in the right industrial floor scale will enhance your operational workflow and accuracy, ultimately improving your business's overall productivity.