Client & Project Overview

Industry: Injection Plastic Molding

Location: Noida, NCR, India

Product Lines: Automotive plastic trims, electrical enclosures, consumer appliance components

Shopfloor Setup: 3 units with 22+ hydraulic and servo-electric injection molding machines (80TĘC350T)

Workforce: 120+ employees (operators, shift leads, maintenance, and QC team)

Project Goal: End-to-end ERP transformation for manufacturing, inventory, quality, and maintenance with real-time visibility and reduced waste.

Challenges & Objectives

Operational Challenges:

- Rejection Rates averaging 8%, largely due to poor inline quality tracking and lack of root cause history

- Inconsistent cycle times across shifts, impacting part quality and delivery planning

- Manual tracking of mold and machine usage, leading to unplanned breakdowns

- Overconsumption of raw materials due to inaccurate stock issuance

- Disconnected departments using spreadsheets, making traceability and planning reactive

Strategic Objectives:

- Implement standardized process controls and enforce inline QC

- Automate work order creation tied to confirmed sales orders

- Enable mold shot tracking and preventive maintenance

- Achieve real-time visibility into OEE, rejection trends, and material flow

- Streamline dispatch, invoicing, and customer order fulfillment

Scope of Work

Odoo ERP Modules Implemented:

- Manufacturing (MRP): BoM-driven operations, routings, machine work centers

- Quality Management: Inline QC, CP/CPK analysis, NCR workflow

- Maintenance: Preventive & condition-based scheduling

- Inventory: Batch-wise tracking, barcode issuance, 2-bin control

- Sales & CRM: From enquiry to order to production linkage

- Purchase & Invoicing: Auto reordering rules, vendor integration

Coverage:

- All 3 shopfloors, 5 major material types (ABS, PP, PC, Nylon, HDPE), 30+ molds, and 200+ SKUs

Solution Design & Implementation

System Design Highlights:

- Machine-Specific Routing: Defined per product based on tonnage, material type, and cycle time

- Mold Shot Counter Integration: Preventive maintenance linked with shot count and part volume

- Inline QC Points & Rejection Reason Mapping (burn marks, short shot, flow lines, warpage)

- Real-Time Material Issuance Control using barcode-based tracking from raw to FG

- Dynamic Capacity Planning integrated with confirmed sales orders

Custom Add-Ons:

- Live Downtime Logging Dashboard by reason (power trip, material jam, tool change)

- Shrinkage Compensation in BoM to ensure net weight accuracy during raw material planning

- Shift-Level Reporting on cycle time variance, rejection %, and operator efficiency

Execution Challenges

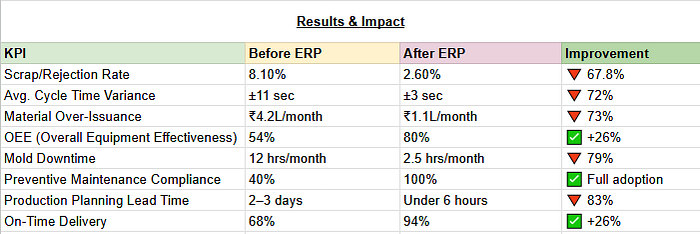

Results & Impact

Client Feedback & Innovations

Client Voice (Paraphrased):

í░We used to spend time fire fighting on the floor. Now, we see the production ecosystem like a cockpit, real-time alerts, shift-wise analytics, and no surprises. Even our mold life is traceable now.í▒

Technical Innovations Delivered:

- Mold Lifecycle Monitoring by Shot Count, reducing mid-run breakdowns

- Rejection Heatmap by Machine & Shift enabling proactive corrections

- Shift-wise Live Dashboard with operator tagging and OEE metrics for supervisors

Key Learnings & Project Team

Key Learnings:

- Digital QC transforms quality ownership from just the QC team to the whole floor

- Mold lifecycle visibility is crucial in sustaining consistent part quality

- Real-time rejection and cycle time tracking improves predictive maintenance and planning

- Operator-level accountability with dashboards fosters performance culture

Project Team:

Client Side:

- Production Manager

- Tool Room In-Charge

- Quality Control Head

- Maintenance Supervisor

ERP Implementation Team (Apagen):

- ERP Strategist & Project Manager

- Functional Consultant - MRP & Quality

- Technical Consultant - Custom Dashboard Development

- Training Lead - Shopfloor Enablement

If youí»re navigating similar challenges in your injection molding operations, whether ití»s reducing scrap, tracking mold performance, or standardizing shift outputs, this transformation shows that structured change is achievable without overwhelming disruption.

Every manufacturing floor is different, but the core issues often rhyme. If youí»re exploring ways to digitize and bring clarity to your operations, weí»re happy to share frameworks, insights, or even just compare notes.

Letí»s keep building better factories, one process at a time through the intelligent and modular system for injection molding.

For more details drop us a mail at sales@apagen.com or call us on +91 9971800665.