They choose appropriate base materials such as FR-4 (a common fiberglass-reinforced epoxy), polyimide, or metal-core substrates depending on the application. High-frequency boards, for instance, may require advanced laminates with superior dielectric properties.

Using the design files provided by engineers (commonly in Gerber format), the manufacturer prints pcb fabrication manufacturer the circuit pattern onto the copper layers. Through processes like photolithography and chemical etching, unwanted copper is removed, leaving behind the conductive traces.

Drilling and Plating**

Modern PCBs often require tiny holes (vias) that connect different layers of the board. Fabricators use advanced drilling machines, including laser drills for microvias, and then plate the holes with copper to create conductive pathways.

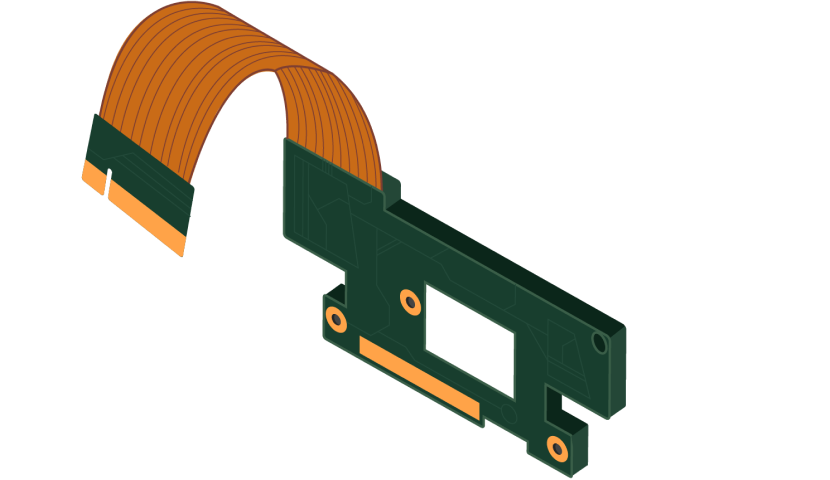

Multilayer PCBs¡ªcommon in advanced electronics¡ªrequire stacking multiple copper and insulation layers together. This lamination process must be highly precise to avoid misalignment or electrical defects.

To protect copper from oxidation and to ensure solderability during assembly, manufacturers apply finishes such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservatives).

Quality control is critical. PCB manufacturers employ optical inspections, electrical testing, and sometimes X-ray analysis to ensure there are no shorts, opens, or misalignments in the circuitry.

Why PCB Fabrication Manufacturers Are Important

The reliability of electronic products depends heavily on the quality of their circuit boards. A poorly fabricated PCB can lead to malfunctioning devices, shorter product lifespans, and even safety hazards. Manufacturers ensure:

They create circuits with microscopic accuracy, often with trace widths and spacing measured in microns.

They produce boards in small prototype batches for testing as well as in large volumes for mass-market products.

They support a wide range of industries with specialized needs, such as high-speed data transmission, high-temperature resistance, or flexible designs.