Strain gauges are specialised sensors designed to measure the amount of deformation or strain in a material when subjected to force. These devices have become an integral part of engineering and testing across industries where structural integrity and precision are vital. As technology advances, the importance of accurate stress measurement in mechanical and electronic systems has only grown, making strain gauges a critical component in many applications.

Understanding the Basics of Strain Gauges

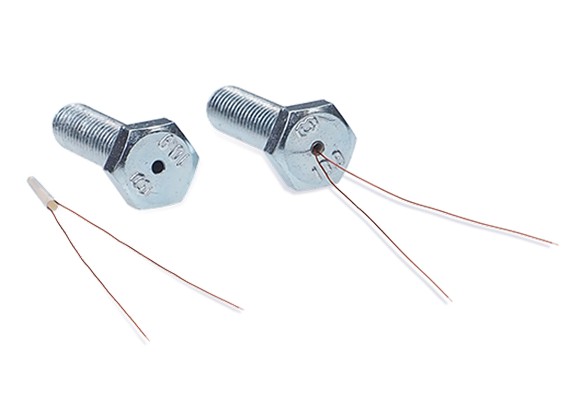

A strain gauge operates on the principle that a material's electrical resistance changes when it is stretched or compressed. Typically, the gauge is made of a fine wire or foil pattern that is bonded to the surface being monitored. When stress is applied to the surface, the gauge stretches or contracts in response, causing a measurable change in its resistance. This resistance change is then interpreted as strain using the gauge factor, a constant that relates the change in resistance to the amount of strain.

The system usually works in conjunction with a Wheatstone bridge circuit, which allows for highly sensitive detection of these resistance changes. This enables precise measurements even when the strain is minimal.

Applications Across Key Industries

The versatility of strain gauges allows them to be used across many different sectors. In aerospace and automotive design, they are used to evaluate the strength of structural components, ensuring that they can withstand operational loads. In civil engineering, strain gauges are applied to buildings, bridges, and dams to monitor deformation and prevent potential structural failures.

Electronics and robotics use strain gauges for tactile sensing, enabling machines to detect force and pressure. In medical research, these sensors are embedded in prosthetics and physical therapy equipment to track movement and monitor stress distribution during use.

Design and Material Considerations

Strain gauges are constructed using various materials depending on the environment and precision requirements. Common materials include constantan, nickel-chromium alloys, and silicon. Each offers distinct advantages in terms of thermal stability, resistance to corrosion, and sensitivity.

The design of the gauge is also critical. Some are meant for single-directional strain measurement, while others are configured in rosette patterns to capture multi-directional strain. The adhesive used to bond the gauge to the test surface must also be chosen carefully to ensure reliable strain transfer and long-term stability.

Importance of Temperature Compensation

Temperature variation can affect the accuracy of strain measurements. As temperature changes, it can cause expansion or contraction in the gauge material, leading to false readings. To counter this, temperature compensation techniques are implemented. These may include the use of dummy gauges, specialised materials, or electronic correction methods that filter out thermal noise.

Without proper compensation, the data collected may be misleading, leading to flawed designs or undetected structural issues.

Installation and Calibration Requirements

Proper installation is essential to ensure accurate strain readings. The surface where the gauge is applied must be clean, smooth, and dry. The gauge must be aligned precisely in the direction of expected strain. Once installed, the leads are connected to the measurement system and calibrated using known loads.

Calibration ensures that the system produces accurate and repeatable results. This step also involves setting a baseline so that the gauge can detect changes relative to a zero-strain state.

Emerging Technologies and Innovations

With the rise of innovative technologies and connected devices, strain gauges have undergone significant evolution. Wireless strain gauges are becoming more common in remote monitoring systems where cables are impractical. These allow data to be transmitted over networks, enabling real-time analysis and predictive maintenance.

Flexible and printed strain sensors are being developed for integration into wearable devices and soft robotics. These can conform to curved surfaces and stretch with movement, expanding the scope of strain measurement into new fields like biomechanics and consumer electronics.

Advancements in materials such as graphene and carbon nanotubes are also contributing to the creation of ultra-sensitive strain sensors. These new materials offer improved durability, better signal-to-noise ratios, and enhanced miniaturisation.

Challenges in Real-World Usage

Despite their usefulness, strain gauges are not without challenges. Installation errors, surface imperfections, and external interference can all affect measurement accuracy. Moisture, electromagnetic fields, and mechanical vibrations can also introduce noise into the signal, complicating data interpretation.

Long-term monitoring applications require careful planning to prevent degradation of the adhesive and protection of the gauge from environmental exposure. Maintenance and periodic recalibration may also be necessary to ensure continued performance over time.

Practical Use in Data-Driven Design

Strain gauges enable engineers and designers to collect data on how materials and systems behave under stress. This information is vital in creating safer, more efficient, and cost-effective products. By analysing strain patterns, it's possible to identify weak points, validate simulations, and optimise material usage.

This makes strain gauges an essential tool in industries focused on structural analysis, quality control, and compliance testing. The ability to collect real-world data during both prototype development and operational use significantly enhances the reliability and longevity of engineered systems.

Conclusion

Strain gauges serve as a bridge between physical deformation and digital analysis. Their ability to convert mechanical stress into quantifiable data makes them essential in fields that rely on precision and structural integrity. As engineering challenges grow and technologies become more advanced, strain gauges will continue to evolve, offering new possibilities in performance monitoring, intelligent sensing, and real-time diagnostics. Their impact on safety, innovation, and efficiency remains significant across every application where force and movement must be measured and understood.